What Is Calandrando?

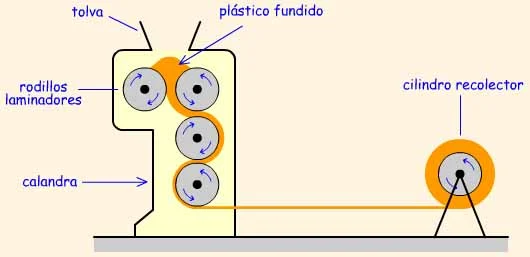

Calandrando, originating from the Italian word “calandrare” meaning to roll or press, represents a sophisticated process employed across industries for the purpose of shaping materials such as textiles, plastics, and paper.

This method entails guiding materials through a series of precisely engineered rollers, subjecting them to controlled pressure and temperature variations to achieve desired outcomes like thickness adjustment, surface smoothening, or texture alteration. Initially rooted in the textile sector, calandrando has evolved over centuries to find extensive utility in various other sectors, thanks to its adaptability and effectiveness.

Also Read: What Is Ilikecomox? All You Need To know In 2024

Historical Overview

The evolution of calandrando can be traced back to the onset of the Industrial Revolution, a period characterized by mechanization and automation. Initially devised for refining textiles, the process gradually expanded its horizons to encompass a broader spectrum of materials and applications. With time, technological advancements refined the calandrando process, enhancing its precision, efficiency, and versatility, consequently broadening its scope across diverse industries.

Principles of Calandrando

Compression and Controlled Pressure Manipulation:

Calandrando relies on the application of controlled pressure to alter the properties of materials. Through compression, materials are reshaped and refined to achieve desired characteristics.

Roller Configuration and Functionality:

Materials are fed between a series of rollers configured in the calandrando system. These rollers play a pivotal role in exerting pressure and shaping the material. They can be heated or cooled to further influence material behavior.

Temperature Regulation:

The temperature of the rollers is a critical parameter in the calandrando process. Heating or cooling the rollers can soften or harden the material, respectively, facilitating desired modifications such as thickness reduction or surface smoothening.

Also Read: Unsuccessful Draft Pick: Everything You Need To Know In 2024

Adjustment of Roller Speed, Temperature, and Pressure:

Precise control over roller speed, temperature, and pressure is essential in achieving specific outcomes during calandrando. Manufacturers meticulously adjust these parameters to tailor the process to the material being processed and the desired results.

Attaining Specific Outcomes:

By fine-tuning roller speed, temperature, and pressure settings, manufacturers can achieve a range of outcomes including thickness reduction, surface smoothening, and embossing. This versatility allows for customization based on the requirements of the final product.

Applications and Uses

Textile Industry:

Calandrando plays a crucial role in enhancing the finish and appearance of textiles. It is utilized to impart smoothness or texture to fabrics, improving their aesthetic appeal and feel.

Plastics Manufacturing:

In the realm of plastics manufacturing, calandrando is employed to produce films, sheets, and laminates with precise thickness and surface characteristics. This process ensures uniformity and quality in plastic products, making them suitable for various applications.

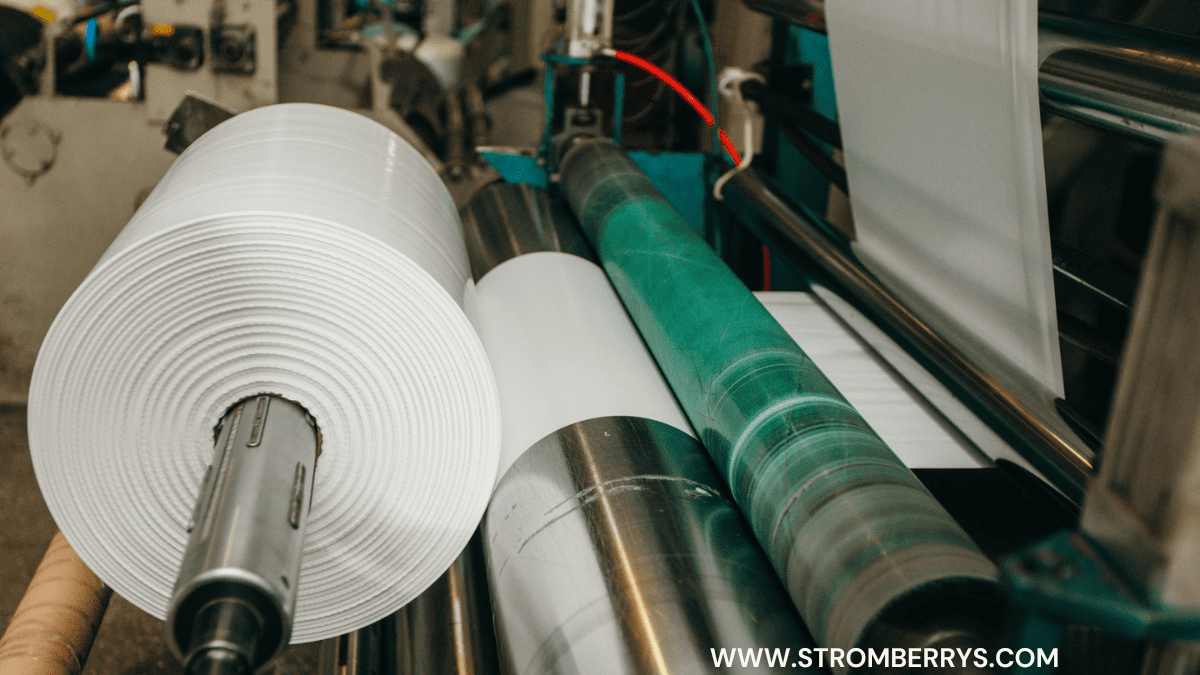

Paper Industry:

Within the paper industry, calandrando serves to improve paper smoothness and printability. By enhancing these properties, calandrando adds value to paper products, making them more suitable for diverse printing and packaging applications.

Calandrando in Industry

Heightened Productivity and Efficiency:

Integration of calandrando into industrial processes enhances productivity by streamlining material processing and achieving desired outcomes efficiently. The controlled nature of the process allows for faster production cycles and reduced downtime, ultimately boosting overall productivity.

Enhanced Product Quality and Consistency:

Calandrando enables manufacturers to achieve a higher level of product quality and consistency by exercising precise control over material properties. This ensures that products meet stringent specifications and customer requirements, leading to greater customer satisfaction and brand reputation.

Cost-effectiveness and Resource Optimization:

The precise control offered by calandrando helps optimize resource utilization, leading to cost savings in material usage, energy consumption, and production waste. By reducing material waste and rework, calandrando contributes to improved cost-effectiveness in industrial processes.

Superior Material Properties:

Calandrando facilitates the production of materials with superior durability, strength, and aesthetic appeal. By enhancing material properties such as tensile strength, tear resistance, and surface finish, calandrando enables the creation of products suitable for a wide array of applications across various industries.

Advantages and Limitations

- Precision and Control: Calandrando offers precise control over material properties, allowing manufacturers to achieve desired outcomes with accuracy and consistency.

- Enhanced Product Quality: By refining material properties and surface characteristics, calandrando enhances product quality, leading to improved performance and customer satisfaction.

- Increased Efficiency: The controlled nature of the calandrando process leads to heightened efficiency in material processing, resulting in faster production cycles and reduced waste.

- Versatility: Calandrando can be adapted to a wide range of materials and applications, making it a versatile solution for diverse industrial needs.

- Risk of Material Damage: Excessive pressure or improper processing parameters can lead to material distortion or damage, highlighting the need for careful process control and monitoring.

- Challenges in Uniformity: Ensuring uniformity in material properties across large production runs can be challenging, requiring meticulous parameter adjustment and monitoring.

- High Initial Investment: The initial investment in calandrando equipment and maintenance costs may be substantial, particularly for smaller manufacturers, posing a barrier to adoption.

- Complexity of Operation: Calandrando operations require specialized knowledge and skill, adding complexity to the manufacturing process and potentially increasing training and operational costs.

Techniques and Methods

Calandrando encompasses a diverse array of techniques and methods tailored to specific materials and applications. Hot calandering involves passing materials through heated rollers to soften and shape them, while cold calandering utilizes unheated rollers for surface finishing and polishing. Additional techniques such as embossing, laminating, and coating can be seamlessly integrated into the calandrando process to achieve desired effects and functionalities.

Innovations and Future Trends

Continual advancements in materials science and manufacturing technologies are driving innovation in calandrando. Emerging trends such as digitalization, automation, and additive manufacturing are reshaping material processing, offering new avenues for customization and efficiency. Furthermore, the growing emphasis on sustainability and eco-friendly practices is fostering the development of greener calandrando processes with reduced energy consumption and environmental impact.

Frequently Asked Questions

What materials can be processed using calandrando?

Calandrando can be applied to a wide range of materials including textiles, plastics, paper, films, and laminates.

What are the primary benefits of calandrando?

Calandrando offers advantages such as improved material properties, enhanced surface finish, increased productivity, and cost efficiency.

How does calandrando differ from other material processing techniques?

Calandrando distinguishes itself by its ability to precisely control material thickness, surface texture, and other properties through compression and controlled pressure manipulation.

Is calandrando suitable for small-scale manufacturing?

While the initial investment in equipment may be significant, calandrando can be adapted to suit both large-scale industrial production and smaller-scale manufacturing operations.

Are there any environmental considerations associated with calandrando?

Efforts are underway to develop greener calandrando processes that minimize energy consumption and environmental impact, aligning with sustainability goals.

Conclusion

In conclusion, calandrando stands as a testament to human ingenuity and technological progress in manufacturing. From its humble beginnings in textile mills to its ubiquitous presence across diverse industries, calandrando continues to shape the materials that define our modern world. As technology advances and new challenges emerge, the evolution of calandrando will undoubtedly persist, driving innovation and progress in material processing for generations to come.